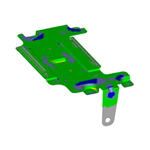

Before taking the plunge on a new metal stamping design, eliminate your risks of material failures upfront. Your metalforming supplier should provide you with a formability assessment early in the quote stage to show any risks and issues before costs are committed.Formability Analysis Software is a valuable tool that quickly identifies areas of concern. After entering 3D CAD data, material type and specifications, the software calculates forming stresses. The suppliers engineering team can simulate the actual forming process, shown in incremental steps, on a computer. The software highlights areas of concern that may cause problems during the form or draw process. These “problem” areas can then be addressed by modifying both the part shape and tooling stations needed to create the finished product. The formability software allows the metalform supplier to communicate potential problems back to you, early in the quote stage. This, in turn, saves you both time and money. What may have taken days or even weeks to develop previously, can now be simulated in the software in a matter of minutes, before any material is cut. The ability to provide feedback about your design concepts, instantly, can certainly help strengthen the relationship between you and your metalforming supplier. The Main Advantages of Formability Analysis: Identifies 90% of forming feasibility issues within minutes, Substantially reduces financial risks during product development, Quickly identifies potential of splitting, wrinkling, and thinning, Accurately predicts feasibility of product geometry, as well as blank size, accounting for material properties, friction and blankholder forces, Saves time during the production and development process. Formability Analysis Software is not only for new designs, but can also be beneficial to existing projects. This software, in conjunction with an innovative engineering team, can find ways to make your current parts better and more cost effective. Find out if your design is as strong as you think it is.